As core equipment for logistics warehousing and cargo turnover, plastic pallet boxes offer diverse types to fit different scenarios. Below are the mainstream types and unique advantages to help enterprises select the right model:

Standard Closed Plastic Pallet Boxes:Fully enclosed design with airtight lids, providing excellent dustproof, moistureproof, and leakproof performance. Made of thickened HDPE, they bear 300-500kg and can be stacked 5-6 layers high, maximizing warehouse space. Ideal for storing liquid raw materials, fresh food, precision parts, and widely used in chemical and food industries.

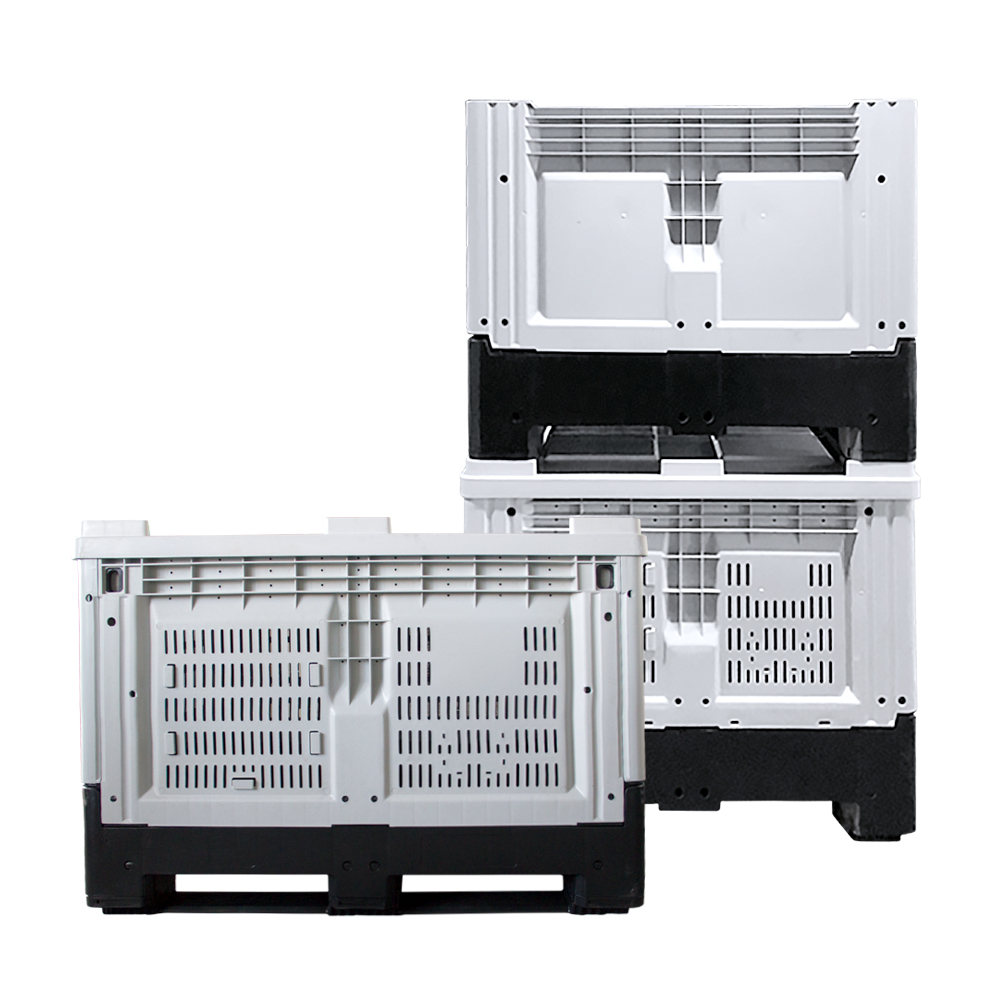

Foldable Plastic Pallet Boxes:Space-saving is their key highlight—empty boxes can be folded to 1/4 of their original volume, significantly reducing empty box transportation and storage costs. With a stable structure when expanded, they bear 200-400kg, suitable for high-frequency turnover scenarios like e-commerce warehousing and cross-border logistics, balancing load-bearing capacity and flexibility.

Grid Plastic Pallet Boxes:Grid-patterned body ensures strong ventilation, facilitating heat dissipation of goods and allowing visual inspection of internal items. Reinforced sidewalls support 250-450kg, perfect for storing fruits, vegetables, mechanical parts, and semi-finished products that don’t require sealing. Easy to load, unload, and clean.

Anti-Static Plastic Pallet Boxes:Added anti-static materials with surface resistance of 10⁶-10¹¹Ω, effectively releasing static electricity to avoid damage to electronic components and precision instruments. Combined with a closed structure and anti-static function, they meet ESD safety standards and are suitable for electronics and semiconductor industries, ensuring cargo transportation safety.

All plastic pallet boxes share common features of wear resistance, recyclability, and forklift compatibility. Enterprises can choose the right type based on cargo characteristics (sealing needs, anti-static requirements) and turnover frequency.

Post time: Oct-31-2025