With the gradual improvement of environmental awareness, wooden pallets are gradually withdrawing from the stage of history. Coupled with the increase in wood prices, their competitive advantage in price is gradually weakening, and plastic pallets have begun to replace wooden pallets. Nowadays, plastic pallets are used in various industries, but how much do you know about plastic pallets?

1.Material

Currently, there are two major categories of mainstream materials in the plastic pallet market: PP and PE. Plastic pallets made of these two materials each have their own advantages and disadvantages, and they can complement each other in practical applications. Simply put, plastic pallets made of PE are more cold-resistant and are more widely used in the food industry, because many foods inevitably need to be stored in cold storage. Plastic pallets made of PP material are more resistant to falling, have stronger impact resistance, and are less likely to be damaged due to improper operation.

2. Brand new materials and recycled materials

Plastic pallets are renewable products. Used plastic pallets will be recycled and remade into raw materials, which is often called recycled materials. Even though plastic pallets made of new materials are durable, different customers will have different needs. For companies that are only used for a short period of time and have low load-bearing requirements, plastic pallets made of new materials are not cost-effective. Generally speaking, the color of the plastic pallet can be used to determine whether it is new material or recycled material. The color of the new material plastic pallet is bright, while the recycled material will be darker in color. Of course, there will also be mixtures, which require more professional technical means to judge.

3. Load-bearing and font shape

The load-bearing capacity of plastic pallets mainly depends on the material and quantity of raw materials, the style of the pallet and whether there are built-in steel pipes. As long as it can meet the needs of the company itself, the weight of the pallet itself should of course be as light as possible, which is not only convenient for management, but also saves transportation. cost. The font of the pallet is mainly determined according to different usage environments. Whether it is a mechanical forklift or a manual forklift, whether it needs to be palletized, whether it needs to be put on the shelf, etc. are all the main factors in choosing the font of the pallet.

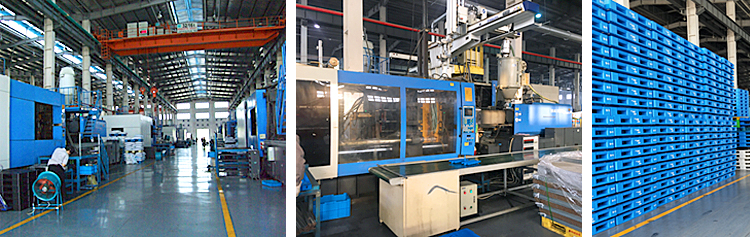

4.Production process

At present, the main processes for plastic pallets are injection molding and blow molding. Injection molding is thermoplastic injection molding, which is formed by injecting melted raw materials into a fixed mold cavity. It is the most common production process. Common flat pallets and grid pallets are both injection molded. Plastic pallets of different styles and shapes are produced according to different needs of customers. Blow molding is also called hollow blow molding. There are usually blow molding holes on the surface of the blow molding pallet, and the middle of the pallet is hollow. The blow molding process can only produce double-sided pallets, and the inlet direction is usually bidirectional. Generally speaking, the price of blow molded pallets is higher than that of injection molded pallets.

Plastic pallets are favored by enterprises in various fields due to their convenience, environmental protection and efficiency. With the continuous development of the Internet of Things, the use of smart pallets will eventually become a development trend. Chips are installed on plastic pallets to allow them to collect information. Transmission, positioning tracking, differentiation and classification are integrated to achieve visual management of the supply chain.

Post time: Apr-26-2024